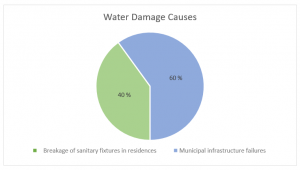

In recent years, the number of claims submitted to insurers has almost doubled. Between 1995 and 1999, about $2.9 billion was claimed annually; this amount then increased to $5.7 billion between 2010 and 2014. The main cause of this increase would be related to water damage. Indeed, since the early 2000s, this type of incident has accounted for more than 50% of all claims.

In addition, broken pipes inside a residence (dishwasher, water heater, flexible connection, etc.) would be the cause of more than 40% of water damage incidents. In Quebec alone, this represents $715 million in claims.

In a previous article (available here), we studied water damages caused by the failure of metal sheaths of the speedways. This time, we will focus on their plastic nuts.

WHAT IS A SPEEDWAY?

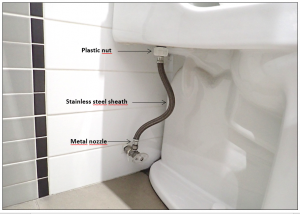

The flexible toilet supply hose, commonly known as the “speedway”, is used to fill the toilet tank. It is a kind of rubber tube covered with a stainless-steel sheath with a metal tip at one end and a plastic nut at the other to allow installation. In the vast majority of supply pipe failures, the nut is responsible.

Photograph 1: Toilet supply pipe installed

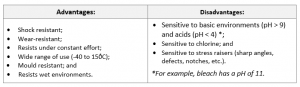

The nut of the supply pipe is made of polyacetal plastic. The table below compares its advantages and disadvantages:

Contrary to what one might think, this is a plastic used in engineering with excellent mechanical properties. However, its causes of failure can be multiple.

Manufacturing problems

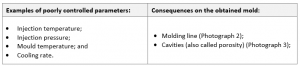

The plastic nuts of the speedways are manufactured using the injection moulding method. The plastic is injected in viscous form into a mould where it is then cooled for solidification. The manufacturing parameters (temperature, pressure, etc.) are determined by the manufacturers.

During this process, poorly controlled parameters can lead to the appearance of manufacturing defects. The table below shows the influence of the manufacturing parameters on some manufacturing defects:

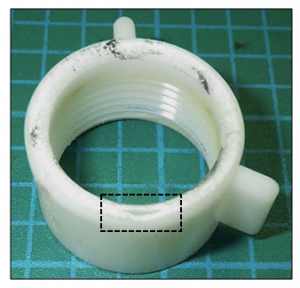

Photograph 2: Molding lines

Photograph 3: Porosity on the fracture surfaces

Poorly designed parts can lead to a decrease in mechanical properties. The plastic nut of a speedway comes from a plastic that is sensitive to stress raisers (sharp angles, thread bottoms, lack of bending radii, etc.).

Poor design and manufacturing defects will thus create a significant decrease in the mechanical properties of the plastic nut hence a decrease of its strength. Over time, cracks will develop and lead to the final and sudden failure of the plastic nut. However, manufacturing and design defects are not the only causes of plastic nut failure.

A poor installation is the cause!

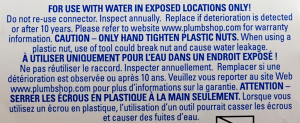

In many cases of expert opinion on the failure of speedways, incorrect installation is observed. Contrary to what is shown in photograph 3, no clamping tools should be used when installing the plastic nut. Indeed, it should only be tightened by hand. For your information, the installation instructions for three speedways we purchased lately insist that the nut be tightened by hand only (photograph 5).

Photograph 4: Poor installation practice Photo Source

Photograph 5: Warning label

Over time, overtightening can cause cracks resulting in the final failure of the nut. Generally, cracks develop in the first thread root, at the location of the seal. Indeed, the presence of thread’s root (a location where the stress is concentrated) combined with pressure of the seal and overtightening of the nut contributes to the development of cracks.

Dégradation by time…

Although the InterNACHI (International Association of Certified Home Inspectors) estimates the life of a residential water main at 50 years, the nut of the speedway may be degraded over time, well before the water main. Among other things, its colour becomes yellowish (photograph 6).

Photograph 6: Unoxidized nut (left) vs. oxidized nut (right)

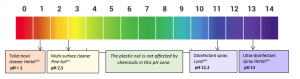

Chemicals and light rays are responsible for the degradation of the plastic nut. A speedway directly exposed to light will have its life span reduced. The same applies to chemicals contained in household products. As explained above, the plastic nut is sensitive to basic (pH > 9) and acidic (pH < 4) environments. The diagram below illustrates some pH values of some household products:

Over time, the chemicals from household products will contribute to the degradation of the speedway. The same is true for chlorine found in water.

In conclusion

The failures in speedways are predominantly caused by the failure of the plastic nut. It may be the result of a manufacturing defect, improper installation or simply degradation over time. Following the manufacturer’s recommendations and regularly inspecting the speedway may help you avoid water damage!

It should be noted that in addition to encouraging customers to comply with installation instructions, manufacturers of speedways have recently reviewed the design of the plastic nut and its manufacturing process. Over time, these improvements may lead to a decrease in the number of breakage cases.

By Marine Herbrecht, B. Sc., Metallurgist, Electrical, Mechanical and Materials team

Photo in header: Source